Description

The Master horizontal trailed mixer wagon is suitable for companies with particular space limitations and with the need to have a fully autonomous wagon in all work phases, equipped with a rear cutter which, with the high developed power, guarantees the loading of any product type.

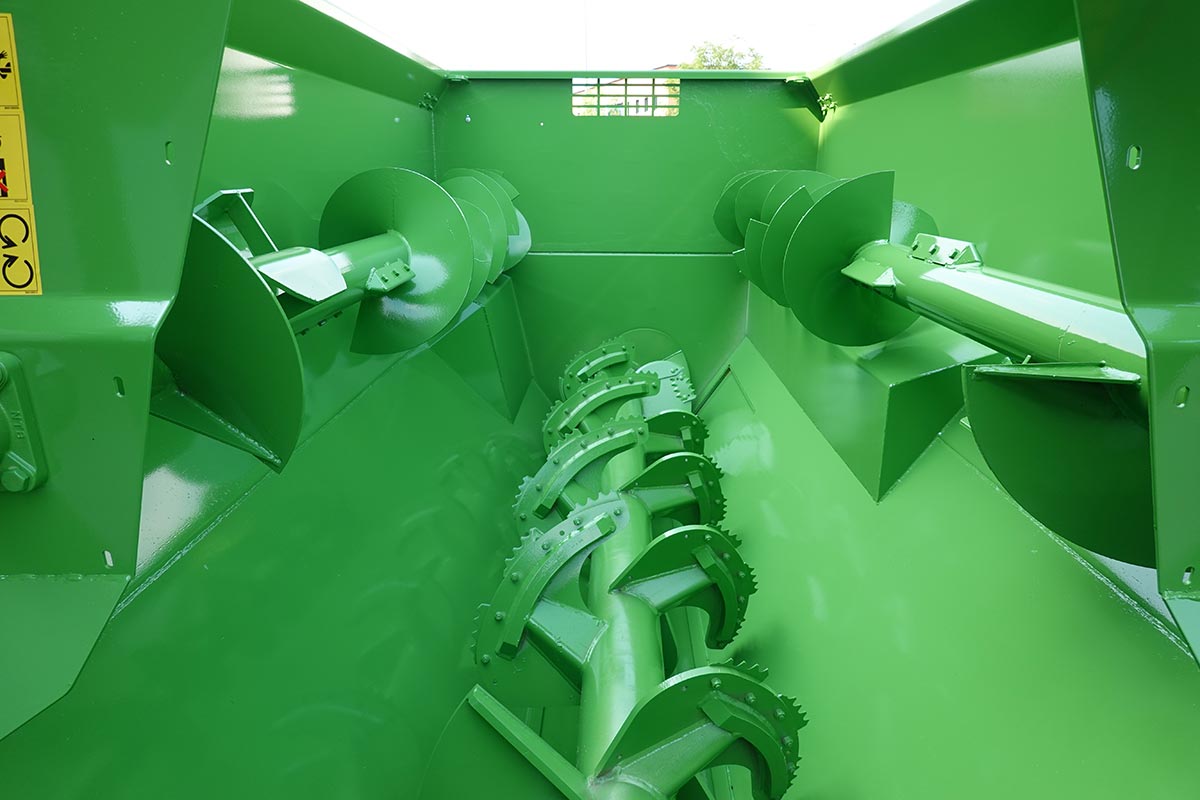

Tub and cutting

The chopping of the product is ensured by the lower cutting auger, which is equipped with a series of self-sharpening blades; these are also effective when processing products (e.g. trees, branches…) with long and dense fibres with a maximum diameter of 0.2-0.23 ft. Above the cutting auger is another auger that aids product mixing and handling.

- S355 steel structure with 0.03 ft thick walls

- Mixing tub bottom 0,03 ft (optional stainless steel 0,02 ft)

- Inspection ladder for checking inside the tub

- Electronic weighing system with 3 sensors

- Reversible and height-adjustable drawbar

- Safety tailgate that can be opened for manual loading

- Standard equipment axle prepared for braking system

Augers

Equipped with three horizontal augers, one of which is a central cutter, and two upper augers, it guarantees excellent mixing of all the ingredients. Remote electric controls and gas damping on the axle provide greater control.

- Upper augers with counterclockwise rotation (optional counter-rotating)

- Upper auger thickness 0,03 ft

- Auger gear ratio 1:38

- Standard equipment electric controls – optional electronic controls

- Standard equipment pump multiplier AC70

Master Cutter

The hydraulic rear tiller has a width of 5.6 ft and an outer diameter of 1.9 ft. The spiral design of the tiller with numerous knives allows silage to be quickly loaded into the box. This is also possible thanks to the two directions of rotation of the tiller, which allow for the best possible loading of the product without throwing any material out of the body.

- Standard equipment with milling cutter only

Discharge

Drain located in the front right position with chain belt equipped with a very wide door that allows rapid flow of product from the mixing tub to the trough. The belts, with a width of 2.9 ft, can be placed in 8 different positions depending on the needs of the user during the forage unloading phase and their exact distribution in the feeder. Furthermore, they can be equipped with speed regulation for optimal batching of the mix.

- Bilateral unloading belt as an option

- Unloading belt at Standard Chains (900×850 mm)

- Rubber unloading belt as an option

Master 3.10 Download Information

Master 3.12 Download Information

Master 3.14 Download Information